Upon walking into a busy laboratory it isn't unusual to see microscopes sitting on books, tilted at odd angles, and otherwise precariously supported in a variety of positions to accommodate their users. Microscopes have undergone a remarkable evolution since their invention in the early 1600s, but most of the new developments and improvements have been in the area of contrast enhancement accessories and the microscope optical train.

While issues of usability have taken a back seat to optical performance for the past 400 years, they haven't been completely disregarded by microscopists. As early as the 1830s, Sir David Brewster noted in his Treatise on Optics, "The best position for microscopical observations is when the observer is lying horizontally on his back . . . . The worst of all positions is that in which we look downwards vertically." Unfortunately, Sir Brewster's suggestions were never utilized in microscope design, and sitting or standing at the instrument became the status quo.

While conventional microscope design has not necessarily been a problem for short-term use, long-term sessions have historically created problems for scientists and technicians who used the instruments, making them, quite literally, a pain in the neck. Microscopists were expected to suffer for the greater good of science and many have paid the price over the years with physical discomfort and sometimes even permanent injuries.

The Occupational Safety and Health Administration (OSHA), in the United States Department of Labor, finds that "Microscope work is straining both to the visual system and the musculoskeletal system. Operators are forced into an unusual exacting position, with little possibility to move the head or the body. They are often forced to assume an awkward work posture such as the head bent over the eye tubes, the upper part of the body bent forward, the hand reaching high up for a focusing control, or with the wrists bent in an unnatural position."

Once an exotic and esoteric piece of scientific equipment, during the Twentieth Century microscopes became commonplace in geological, biological, and medical laboratories and in factories manufacturing electronic components and integrated circuits for computers and the consumer electronics industry. As microscope use grew, so did concerns about usability. During the 1980s and 1990s, microscope manufacturers began introducing ergonomic features into their instruments to make them safer and more comfortable to use for extended periods of time (up to six or eight hours a day).

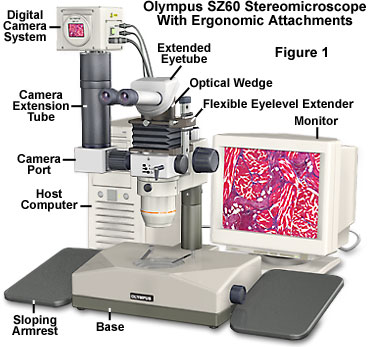

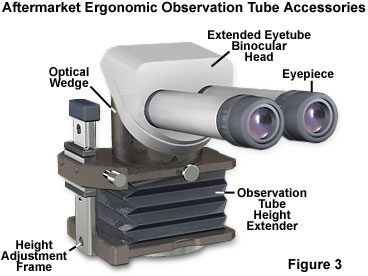

Illustrated in Figure 1 is a 1980s era Olympus SZ60 stereo microscope equipped with several aftermarket ergonomic accessories. To ease operator posture, the microscope is fitted with an extended set of eye tubes (also see Figures 3 and 4), an optical wedge that places the observation tubes closer to a horizontal angle, and a flexible adapter that allows the individual user to adjust the microscope's height. Adjacent to the microscope is a pair of sloping armrests that eliminate the necessity to remove arms from the laboratory bench in order to adjust the microscope. The SZ60 was designed during a period when stereo microscope focus controls were mounted high on the rack, and required considerable forearm motion to continually adjust focus. In addition, magnification is altered by rotating a large knurled ring in the central portion of the microscope body. This ring contains several pairs of Galilean telescopes that increase or decrease magnification. Operation of the microscope for extended periods of time requires constant changing of both focus level and magnification factor, both of which have controls located a significant distance from the desktop. A digital video camera system is attached to the microscope through an aftermarket adapter. Operating the microscope with the camera enables the operator to compose and focus images on a computer monitor instead of through the microscope eyepieces, thus potentially reducing eyestrain.

Basic Ergonomics

Ergonomics is concerned with finding a better fit between people and the things they do, the objects they use, and the environmental setting in which they live, work, travel, and play.

The science of ergonomics is the study and application of human anatomy, biomechanics, and biology to the design of objects, systems, and environments. Also called human engineering, or human factors, it is a relatively new branch of science that was founded in 1949, spurned by the development of new technologies during World War II. Throughout this period, it had become clear that, in order to be used safely and effectively, new technologies and products needed to account for human and environmental factors. Over the past 50 years, ergonomics has become widely applied, in areas ranging from factory work and information systems to the home, sports, and leisure—nearly every aspect of life.

In the workplace, the goal of ergonomics is to improve efficiency, quality, and job satisfaction by making routine and repetitive tasks more comfortable and easier to perform. This reduces stress, both physical and psychological, by lowering the fatigue factor and reducing human error. In some jobs, particularly in the nuclear and chemical industries and transportation (for example, air traffic control), the cost of human error can be catastrophic, injuring or killing hundreds of people or resulting in widespread environmental disasters.

Percentage of Microscope Operators

Reporting Medical Problems

| Anatomical Location | Employee Percentage |

|---|---|

| Neck | 50-60 |

| Shoulders | 65-70 |

| Back (Total) | 70-80 |

| Lower Back | 65-70 |

| Lower Arms | 65-70 |

| Wrists | 40-60 |

| Hands and Fingers | 40-50 |

| Legs and Feet | 20-35 |

| Eyestrain | 20-50 |

| Headaches | 60-80 |

Table 1

For the vast majority of jobs, however, it is the individual workers who are primarily affected, suffering discomfort, injuries, or outright disabilities, classified as work-related musculoskeletal disorders (MSDs or WMSDs). MSDs are medical conditions affecting the muscles, nerves, tendons, ligaments, joints, cartilage, and/or spinal discs. MSDs are referred to by a number of names (and acronyms). The terminology includes Repetitive Strain Injuries and Repetitive Stress Injuries (RSIs), Cumulative Trauma Disorders (CTDs), and Overuse Syndrome, although these are umbrella terms and don't refer to any MSD in particular. Some examples of specific MSDs are carpal tunnel syndrome, tendonitis, ganglion cysts, and lower back pain. General warning signs of MSDs are fatigue, stiffness, persistent burning or aching, reduced coordination, and a loss of grip strength in the hands.

Numerous studies have established the following ergonomic risk factors as most likely to cause or contribute to an MSD: force, repetition, awkward postures, static postures, vibration, contact stress, and cold temperatures. Of these risk factors, force (specifically, forceful exertions), repetition, and awkward postures are most often associated with the occurrence of serious MSDs.

Exposure to one ergonomic risk factor may be sufficient to cause or contribute to an MSD. Most often, ergonomic risk factors act in combination to create a hazard. Jobs that have multiple risk factors have a greater likelihood of causing an MSD, depending on the duration, frequency, and/or magnitude of exposure to each factor. It is important to consider ergonomic risk factors in light of their combined effect in causing or contributing to an MSD, as well as their individual effects.

Ergonomics has become a topic of increasing importance in the workplace during the past several decades. A mismatch between the physical capacity of workers and the physical demands of their jobs can result in MSDs. In the USA, 1.8 million workers report work-related MSDs such as carpal tunnel syndrome, tendonitis, and back injuries, every year. Approximately 600,000 MSDs are serious enough to warrant taking time off from work to recover, and sometimes they even require surgical intervention. There is evidence that another 1.8 million MSDs go unreported every year.

MSDs are estimated to cost up to $50 billion a year. Employers pay between 15 and 18 billion dollars in workers' compensation costs alone; one of every three dollars spent on workers' compensation goes for MSD-related claims. This does not include billions of dollars spent on medical treatment and hidden costs associated with work-related injuries. Recent increases in reported MSDs suggest that employers should be vigilant in creating work environments that are conducive to both good health and high productivity.

Microscope Ergonomics

The human body is a biomechanical wonder, accommodating and adapting to a wide variety of postures and activities. The key word for a healthy, well-maintained body is "activity." The human body functions at its best when it is constantly moving or changing positions.

Sitting or standing for hours on end, bent over a microscope eyepiece is not an activity for which the body is well adapted. Microscope work requires the head and arms to be held in a forward position and inclined toward the microscope with rounded shoulders, a posture that can irritate soft tissues, such as muscles, ligaments, and discs. If the feet are placed on the ring-style footrests that are common to many lab stools, the position is further exaggerated.

Poor posture and awkward positioning are the primary risk factors for MSDs that can affect full-time microscopists, who often experience pain or injury to the neck, wrists, back, shoulders, and arms. Eyestrain, leg, and foot discomfort have also been documented with long-term microscope use. In the semiconductor industry, the second leading cause of work-related medical problems is found in microscope technicians, trailing only maintenance workers, who traditionally have high injury rates. A regional survey of cytotechnologists, heavy users of microscopes, found that slightly over 70 percent reported having neck, shoulder, or upper back symptoms, while 56 percent had an increased incidence of hand and wrist symptoms.

Other studies have revealed that approximately 80 percent of microscopists in all fields have experienced job-related musculoskeletal pain and that 20 percent have missed work because of medical problems related to microscope use. The rather high 5- to 10-year drop out rate for cytotechnologists is attributed, in part, to physical discomfort associated with long hours examining specimens through the microscope. Table 1 lists the range of percentages reported in the literature for medical complaints associated with long-term microscope use. A majority of reported problems occur with the neck, back, shoulders, and arms, with a smaller percentage of microscopists reporting discomfort or injury to the wrists, hands, legs, feet, and eyes.

Many of these conditions can be avoided or at least mitigated. Two studies at Duke University Medical Center during the 1990s suggested that people suffered fewer discomforts when using new ergonomically designed microscopes or even conventional microscopes modified to better accommodate the user. In either case, adaptability was the key to improved comfort. Microscopes that could be adapted to an individual user, rather than forcing the user to adapt to the microscope, were more comfortable and caused fewer problems.

Factors believed to be the cause of these problems are head inclination up to 45 degrees and upper back inclination at angles up to 30 degrees, awkward positioning of the arms and hands, and repetitive motions. An unaccommodating workstation that requires a microscopist to sit in awkward positions for long periods can also cause fatigue and MSDs.

Proper Microscope Posture

Explore how new ergonomic microscope designs aid the operator in assuming a more correct posture for seated observations, as a function of height.

The major ergonomic factor in the employment of conventional microscopes is that viewing specimens requires users to maintain a flexed neck posture while the hands must remain in a relatively fixed position. From the standpoint of biomechanics, having to maintain even a slight incline of 30 degrees from the vertical can produce significant muscle contractions, muscle fatigue, and pain. Furthermore, it has been documented that pinched nerves can occur when the neck is overextended by this amount. Repetitive motions of the hands and the contact stress of arms resting on a hard surface can cause pain and nerve compression, leading to repetitive stress injuries and/or carpal tunnel syndrome.

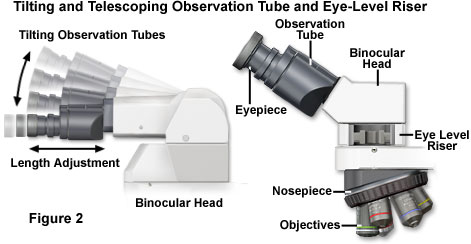

Recent studies have suggested that to permit a more neutral erect working posture, the optical path (distance from the ocular lenses to the specimen being viewed) should lie in the range between 45 and 55 centimeters (18 to 21.5 inches). The eyepieces should be angled no more than 30 degrees above the horizontal plane of the desktop (Figure 2). A majority of older microscopes, however, have much shorter optical path length (25 to 30 centimeters or 10 to 12 inches) with the eyepieces angled at 60 degrees above horizontal.

This configuration creates a dilemma for the user. If the microscope is raised to a sufficient height to prevent neck flexion, then the user is forced to bend the wrists into an unnatural position. If the microscope is lowered to bring the stage to a more neutral position, with the forearm parallel to the floor, then the neck is forced to bend. Most workers compensate for this by finding some "happy medium" between the two extreme postures, resulting in discomfort for the neck, shoulders, forearms, wrists, and hands.

Eye fatigue can be another major problem for microscope operators, especially if they have poor vision resulting from near or far sightedness, or astigmatism. The diopter adjustment provided on most microscope eyepieces can be employed to compensate for minor focus problems (near and far sightedness), but microscopists who have moderate to severe astigmatism should wear glasses when viewing specimens through the eyepieces. In order to accommodate the longer eyepoint necessary for observation with eyeglasses, manufacturers offer specialized high eyepoint eyepieces. Many eyestrain problems that develop during extended periods of microscope use can be alleviated by employing video camera systems that display the specimen on a computer monitor or television screen. In fact, many future microscope designs may eliminate the eyepieces altogether, substituting instead a CCD or CMOS image sensor for the classical observation tubes. The digital imaging chip will be coupled to a sophisticated software analysis package that controls image capture and storage, digital processing, and other features such as time-lapse cinemicrography and real-time video movies.

Ensuring that the microscope images are as bright, sharp, and crisp as possible will also help to reduce eye fatigue and associated headaches. It is important to train operators in correct alignment of the microscope lamp and optical pathway to optimize image quality. This is true regardless of whether the image is observed through the eyepieces or on a computer monitor. Many of the newer microscopes feature expanded viewfields through the use of eyepieces with larger field diaphragms. Coupled to objectives with higher numerical aperture values, better aberration correction, and longer working distances, the images produced show a tremendous amount of specimen detail in exquisite clarity with flat fields from edge-to-edge. These factors ease the burden of visually searching for tiny specimen details, and reduce associated eye stress and fatigue during extended periods of observation.

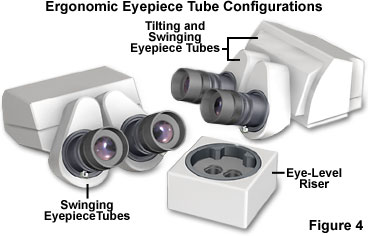

Some companies now produce adapters that allow conventional microscopes to be modified to better fit individual users (Figures 1 through 4). Body tube extensions can increase the distance between the eyepieces and stage controls, and optical wedges can provide a greater angular range of adjustability, between 30 and 80 degrees. Aftermarket microscope stands allow an instrument to be elevated and rotated for increased comfort.

A recent solution to the problem of microscope usability has been the incorporation of ergonomic features into modern designs by the microscope manufacturers. Although these models were prohibitively expensive for the vast majority of laboratories when they were first developed, ergonomic features are increasingly becoming standard on new microscope models in all price ranges.

Another study carried out at Duke University examined the new ergonomic designs with a group of cytotechnologists who used traditional microscopes in their work, and who had a variety of complaints associated with using that equipment. The study replaced conventional Zeiss model microscopes, used by the workers, with a modern ergonomically-designed laboratory microscope having a tilting and telescopic head, optional eye-level riser tubes, single-hand focus controls, and in-line focusing. Users were significantly more comfortable in the neck and shoulder regions after switching to the ergonomic design, indicating that redesigning microscopes with posture and ease of manipulation in mind will help to reduce discomfort associated with long hours of use. The study also showed that symptoms of eye fatigue and mid-back discomfort decreased, though not to a statistically significant degree. Eliminating or reducing eye fatigue is most easily accomplished by equipping the microscope with a digital video camera that displays specimen images on a television screen or computer monitor. As mentioned previously, this allows operators who have eye problems, such as myopia and astigmatism, to comfortably wear their glasses during inspection of specimens.

New Microscope Designs

The microscope manufacturers have been instrumental in stepping up the pace of ergonomic development, with new designs featuring the latest technology to ease operator fatigue and reduce stress levels and associated health problems. Microscopes can be broadly divided into four categories: stereo microscopes, upright compound microscopes, reflected light microscopes, and inverted microscopes. Each class is designed for a specific type of observation, and each has its own unique ergonomic requirements, although there are many shared attributes. The most important features are operator control, posture boundaries, eye-level adjustment, stage placement, instrument body and stand rigidity, and specimen handling. All of these specifications are discussed in detail for each microscope class in the following sections.

Stereo Microscopes

Stereo microscopes, the largest segment of the microscope market, with a share of about 50 percent of total microscope sales, are the focus of many new ergonomic features. Each year over 20,000 of these ubiquitous and popular instruments are sold to educators, researchers, and industrial manufacturers. Traditionally, stereo microscopes are constructed with the body and eye tubes mounted on a long pillar that allows specimens having a wide spectrum of sizes to be examined and manipulated. The eye tubes in older stereo microscopes are fixed into position, usually at a 45 to 60 degree angle from the horizontal bench, and the focus knob is mounted high on the body near the pillar rack. This design has a number of significant ergonomic drawbacks and has taken a heavy toll in operator trauma over the years.

Recent advances in stereo microscope design have addressed the many ergonomic issues facing manufacturers who employ large numbers of technicians that spend long periods examining and manipulating specimens with these popular microscopes. The primary concentration has been on eyepiece tube inclination angles and the height of the tubes in relation to the laboratory bench top. Inclination angles have been modified in current microscope designs to include low eye-level and tilting tubes, which offer a wide range of adjustments to fit the needs of operators who span a large range of body sizes and heights (Figures 2 to 4). These re-designed eye tubes allow comfortable observation regardless of whether the microscopist is sitting or standing, and enable the utilization of eye-level risers, intermediate tubes, and photography ports without compromising operator comfort. Coupled to advanced eyepieces with a high eyepoint, diopter adjustments, and large field numbers, modern stereo microscope observation ports have made significant strides in ergonomic design and have led to improved efficiency with fewer medical incidents.

Another ergonomic feature incorporated into recent stereo microscope designs involves lowering the position of focus knobs to ensure quick, accurate, and effortless focusing of specimens. Located within easy reach of the operator, the lowered focus knobs eliminate the need for twisting the shoulders while adjusting the microscope focus. This feature, alone, has significantly improved stereo microscope operation, especially for technicians who must examine large complex objects that require constant focus adjustments.

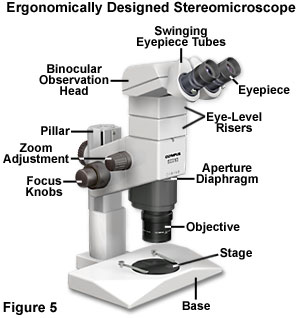

Presented in Figure 5 is an illustration of a late model state-of-the-art stereo microscope designed by Olympus, the SZX. This instrument features lowered focus knobs, an eye-level riser intermediate piece, and ergonomic tilting eyepiece tubes to increase user comfort and reduce the amount of fatigue and stress associated with operation of the microscope. Also available for this microscope are a number of accessories including an ergonomic 1x objective, which allows the operator to control eye-level position, and extended eyepiece tubes that further modify the viewing angle. The eyepieces have an adjustable diopter range and are made with high eyepoint to ease the burden of wearing glasses while observing specimens in the microscope.

New ergonomic auxiliary objectives, designed specifically for stereo microscopes, aid in establishing the correct eye-level position by allowing the operator to freely adjust focal lengths to match seating requirements. Streamlined microscope bases with a variety of illumination capabilities also enable operators to manipulate specimens while resting their arms in a natural position. Longer working distance objectives that offer excellent aberration correction, high numerical apertures, and improved light transmission add further to operator comfort and reduction of fatigue.

Traditional Upright Compound Microscopes

Following stereo microscopes, upright compound microscopes command the greatest market share and are sold by the thousands every year. The design of these microscopes has also received considerable attention from the manufacturers with respect to ergonomic factors. Included in the new list of features are one-handed stage and focus control, optimum eye-level positioning (Figure 2), low-profile stages, and rigid instrument body standards, all contributing to strain-free posture for operators while examining specimens.

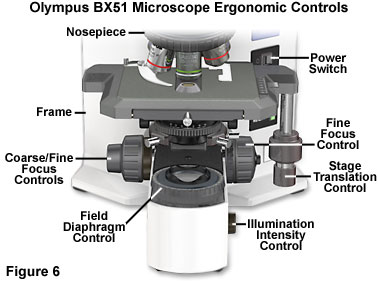

Perhaps the most significant feature of new compound microscope designs is positioning of the stage translation and focus control knobs in an equidistant configuration from the operator (Figure 6). This allows a more relaxed posture with the hands resting comfortably on the desktop. In addition, operators are no longer required to twist their shoulders to simultaneously manipulate the stage and focus controls, considerably reducing the amount of strain associated with long-term observation. Other frequently used microscope controls, such as the field diaphragm, light intensity potentiometer, and auto-illumination photomicrography preset switch, are located in the front of the microscope base at desktop height and within easy reach of the operator (see Figure 6 for details). Push-button filter engagement levers are also positioned near the main controls to further enhance operational ease. Many microscopes are equipped with a refocusing stopper that allows quick change of specimens with an instant return to focus. In addition, coarse focus tension controls allow the operator to customize the action of z-direction stage translation to suit individual preferences. A few microscopes also offer detachable fine focusing knobs that can be fitted to either side of the instrument to suit the operator's preferences, and some knobs are coated to enhance traction and allow easy operation with only a single finger.

Lowered stage assemblies, in recent instrument designs, have heights ranging from approximately five to eight inches, considerably lower than those found on previous microscopes. Many also incorporate space-saving dual pulley or pulley and guide rod systems that replace older rack and pinion mechanisms to govern stage movement. Some models feature focusing adjustments that translate the nosepiece, rather than the entire stage, to maintain a constant stage height, reducing the amount of forearm movement necessary to move the stage or change the specimen. More advanced designs eliminate protrusion of the x-directional guide from the side of the stage, thus reducing interference with focusing action. Rotational movement of modern stages often exceeds 200 degrees and some can even achieve over 250 degrees of rotation about the microscope optical axis. Any microscopist who has spent time framing images for capture on film or by digital imaging will appreciate this advanced feature, which not only saves time, but eliminates a considerable amount of frustration.

Eyepiece tube angles are almost infinitely adjustable on some of the latest microscope designs (Figures 2 and 4). In addition to a tilt range between 25 and 40 degrees, some binocular tubes have a telescoping adjustment that enables the eyepieces to be moved backward and forward over a span of 30-50 millimeters to accommodate the operator. Microscopes can be fitted with eye-level riser blocks to increase the height of eyepiece tubes and some have eyepoint adjusters, which employ swivel joints to increase or decrease the height of the eyepoint position relative to the desktop (Figure 4). The result is that almost every microscopist, regardless of size and height, can peer straight into the eyepieces without tilting the head, a considerable improvement in design that ensures a comfortable working position. Even when the posture inevitably changes after several hours of observation, the eyepoint can be adjusted to match the new position and reduce fatigue. Easy diopter and interpupillary distance adjustments in modern eyepieces also serve to reduce operator discomfort, and reduced diameter eyepiece lenses in some models aid observation by operators with deep eye sockets.

A majority of new microscope designs incorporate pre-centered illuminators allowing rapid bulb replacement, and some even feature pre-centered condensers. These elements allow the operator to concentrate on specimen observation with a minimum of disruption to reconfigure the microscope after lamp failure. In addition, some objectives are intensity equalized to reduce the necessity to adjust illumination intensity when changing objectives, thus eliminating the discomfort of exposure to sudden changes in light intensity when rotating objectives. Designs incorporating lowered nosepieces also reduce operator fatigue by allowing the arms to rest on the desktop while changing objectives.

Modern microscopes are designed with the help of computer-aided engineering (CAE) to achieve both high vibration resistance and structural rigidity to ensure that these instruments operate at peak optical levels. Vibrations and base deformations lead to image deterioration, which is manifested in bad photomicrographs and/or digital images. This is also a leading cause of fatigue and frustration by the microscopist intent on capturing the best images possible. Collectively, the new ergonomic features of today's upright compound microscopes enable observations over extended periods of time with a minimum of stress and fatigue, enhancing both the performance and efficiency of the microscopist.

Reflected Light Microscopes

Industrial reflected light widefield and confocal microscopes are becoming increasingly popular as process monitoring and quality control tools in the booming semiconductor industry. Operators attending workstation monitors in wafer assembly plants often spend up to eight hours a day examining integrated circuits for defects, improper mask alignment, and process errors. Paramount in the development of these microscopes is an advanced optical system providing superior illumination, greater depth of focus, highly corrected objectives, and contrast enhancing light conditioners. The instruments are often equipped with specialized stages designed specifically for rapid manipulation of wafers having varying dimensions (Figure 7). To increase stability, semiconductor inspection microscopes are built with rigid and sturdy bases having sufficient weight to resist blur and image shifts induced by floor vibrations.

Several standards have been adopted by the semiconductor industry (SEMI S2-93A and S8-95) to provide safety and ergonomic features for microscopes designed to be operated in wafer fabrication plants. Among the requirements for these instruments are controls and knobs that are positioned low and close to the operator while the eyepoint is set at the proper height for comfortable operation. The manufacturers have designed microscopes that have focus, illumination, and objective controls positioned in the base, beneath the stage and directly in front of the operator or in a separate keypad that can be conveniently located. These features minimize hand movement and enable "blind" operation, which reduces the distraction of a search for adjustment knobs or manual rotation of the objectives. In addition, most models have eyepieces moved to a forward position on the microscope where they are located closer to the operator, allowing a more erect seated posture. The latest microscopes are equipped with tilting eyepiece tubes that provide continuous adjustment of the tilt angle through a range of zero (horizontal) to 45 degrees for viewing at the optimum eyepoint level. Some models also have telescoping tubes that enable the operator to shift the viewing position closer to or farther away from the microscope body and some even incorporate image-erecting prisms. These features are important in situations where operators must inspect wafers in a standing position, and are thus subject to a more rapid onset of fatigue.

Stage evolution has also occurred in the design of modern industrial microscopes. Many feature custom wafer and mask holders that attach directly to the manually operated or motorized stages or allow the microscope to be interfaced with wafer loaders. Stage control has also been the focus of ergonomic considerations, and the x-y fine movement translators in many semiconductor microscopes do not move with the stage. Instead, they are placed close to the front of the microscope in a lowered position, which allows the operator to control movement without lifting the arms. These controls are also located near focus, illumination, and objective rotation buttons, enabling the microscope to be operated with one hand. In addition, many stages feature a coarse/fine selectable movement control having an electric clutch handle that allows the operator to quickly navigate to a selected area, then zero in on fine details with a minimum of effort.

Other features, such as motorized nosepieces, tilting breath shields, remote focus handles and jog dials simplify operation of industrial microscopes. High-end models feature illumination blanking when objectives are rotated to protect the operator's eyes from bright light flashes. Remote keypads on reflected light confocal and widefield microscopes now control epi-polarizer rotation, aperture diaphragm opening size, epi/diascopic illumination selection, focus, stage position, and observation mode selection. Together, these ergonomic considerations have dramatically improved the efficiency of semiconductor inspection operations, while simultaneously reducing the health risks associated with long hours spent at the microscope.

Inverted Microscopes

A dramatic transition of fluorescence microscopy and electrophysiology to the forefront of biomedical research has occurred over the past ten years. In this regard, inverted microscopes designed to examine and manipulate cells and tissues in culture have simultaneously acquired ergonomic features to increase operator comfort and reduce fatigue. Frequently utilized control elements, such as focus, illumination intensity, optical path direction, and stage translation, have been moved to the front of these instruments to increase operation efficiency and minimize operator stress and strain.

Like other modern designs, inverted microscopes are equipped with adjustable eyepiece tubes that allow the operator to alter the eyepoint height over a wide range with respect to the desktop. On many microscopes, the tubes can also be rotated over more than a 90-degree range to increase flexibility in specimen examination and manipulation. Additional observation tube accessories include auxiliary magnification and Bertrand lenses (for phase ring alignment), and some models are equipped with a light-limiting shutter and built-in photo reticle.

Stages on inverted microscopes have been redesigned to afford lower heights with ample room for incubators, large culture vessels, in vitro fertilization micromanipulator systems, electrophysiology attachments, and patch clamp accessories. Translation handles are often mounted with universal joints to allow simultaneous focus operations while the specimen is being scanned. Beneath the stage, larger nosepiece clearance and revolution grips enable operators to identify and rotate objectives more quickly and efficiently. The combination of these features helps to reduce operator MSD complaints resulting from extended observation periods.

Other features common on high-end research inverted microscopes include tilting illumination pillars, threaded installation holes for accessories, and condenser/stage refocusing stopper combinations. On inverted microscopes, the pillar supports a long working distance condenser and usually a tungsten halogen lamp house for brightfield, darkfield, phase contrast, and differential interference contrast illumination. Some microscopes are equipped with a detachable pillar that can also be tilted backward up to 45 degrees to allow micromanipulation equipment to be installed or to change specimens without raising the condenser. These features ease the burden of complex and repetitive microscope reconfiguration, and are a much-improved ergonomic design over that of previous models. Refocusing stoppers allow the operator to quickly rack down the coarse motion to change specimens and return to the exact focus point. Likewise, condenser-refocusing stoppers eliminate the need for the operator to manually replace the condenser into the correct focal position. Once set, the stopper enables a quick changeover of specimens with a rapid return to the preset condenser focal point.

Current inverted microscope bodies are now much sturdier and heavier than their former counterparts. This dramatically reduces vibration and provides long-term stability for examination and manipulation of specimens and the utilization of time-lapse cinemicrography, digital imaging, and photomicrography techniques. Collectively, the new ergonomic features on inverted microscopes have come a long way toward easing the fatigue associated with long periods at the microscope, while at the same time, increasing the efficiency and health of microscopists who spend countless hours investigating the mysteries of life.

Aftermarket Ergonomic Products for Older Microscopes

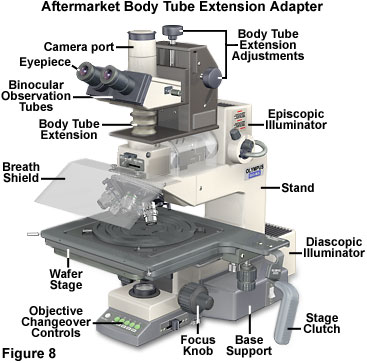

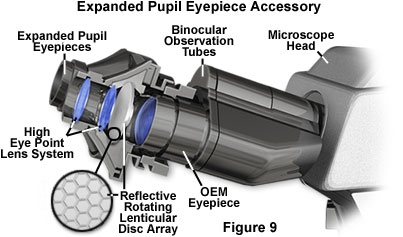

A number of aftermarket products designed to enhance the usability of microscopes are now available from a variety of manufacturers. Included in this new array of ergonomically designed add-ons are extended eye tubes for binocular observation heads (Figure 3), armrests, eye-level height extenders, lenticular microarrays to ease viewing specimens (Figures 9 and 10), digital viewing screens, bellows-type body extensions (Figure 8), optical wedges, and ocular-less digital imaging video systems.

Extended eye tubes (Figures 1 and 3) are considerably longer than conventional models and enable the operator to move away from the bench while maintaining a more supported neutral posture during extended observation periods. Observation tubes are available in lengths up to 90 millimeters, which is ideal for microscopes placed near machines, heating stages, solder stations, or in fume hoods. In addition, the extended tubes provide an additional magnification factor of almost 2x, which compensates for the decrease in magnifying power accompanying long working distance objectives. Several models also offer larger interpupillary adjustments (up to 90 millimeters to accommodate all users) and are designed to maintain parfocality and true optical alignment throughout the working-angle range of the observation tubes.

A useful and easily adapted product is the optical wedge, which adds flexibility in configuration of the eye level height. This attachment is positioned between the binocular head and the body of the microscope to provide expanded viewing angle adjustment and added operator comfort. The optical wedge can be coupled to flexible body-extending adapters (Figures 1 and 3) to provide a wider range of eyepiece height adjustment, thus allowing the microscopist to assume a more neutral posture. A locking knob is utilized to vary the adapter height, and most units of this type allow rotation of the observation tubes from side to side to increase flexibility in microscope configuration.

Microscope positioning plates are also available to raise, lower, or tilt the microscope into a position that meets the ergonomic requirements of the operator's body dimensions. These devices consist of an adjustable base plate that enables the microscopist to raise the instrument height between 1.5 and 4 inches, and stacker plates can be added to attain even greater heights. Individual legs on the positioning plates are adjustable to allow tilting of the microscope, and to provide a high degree of precision with respect to instrument height and viewing angle.

Increasing the field of view and the distance from the observer's eyes to the microscope has been the target of a growing number of aftermarket products. Utilizing lenticular array technology, Vision Engineering has introduced a new ergonomic accessory termed Isis, which can be retrofitted to existing microscopes by insertion into standard observation tubes (Figure 9). This product increases the effective distance of the eyes to about 38-40 millimeters from the eyepieces, expanding the pupil image and providing the operator greater freedom of head movement with better posture. The manufacturer also claims that Isis reduces the distraction of eye floaters, which move across the field of vision and are accentuated by viewing specimens in bright illumination.

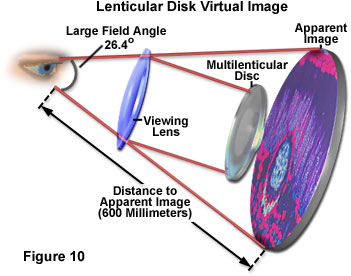

Lenticular array technology is based on a rotating optical disk that contains several million tiny individual microlenses (termed lenticules) that act in concert to expand the depth of focus and field of view when the disk is spun at high rotational speeds (Figure 10). The transparent disks are about 15 millimeters in diameter and are utilized in either a transmitted or reflected mode to enhance observation. Each of the individual lenticules is about 70 micrometers in size, but they are merged to deliver a smooth image when the disk is spun at speeds up to 3,500 revolutions per minute.

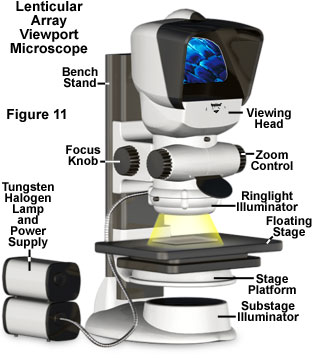

More advanced applications of lenticular array technology are manifested in microscope designs that employ viewing heads in place of eyepieces (Figure 11). First applied to stereo microscopes, this approach substitutes a lenticular array-driven screen that is positioned on top of the microscope body to allow the operator wide latitude in viewing angle and distance. Operators who wear eyeglasses can easily view specimens for long periods of time without the discomfort associated with repeated re-focusing when the glasses are removed. These microscopes are also designed with ergonomic standards in mind, and have focusing, zoom, and illumination adjustments that are positioned low on the base for easier operation.

Another new technology, which does not require eyepieces or lenticular arrays, substitutes a CCD or CMOS image sensor to capture and display the image on a computer monitor, as discussed previously. Although this configuration is easily attainable with current instruments by simple addition of a digital camera system, the eyepiece-less microscopes are accompanied with software packages that aid in image capture, and feature a number of applications such as multiple file storage formats, digital image processing software, and time-lapse cinemicrography. The versatility of these systems should ease the fatigue and stress associated with long term microscope use and increase operator efficiency through enhanced software features.

The importance of proper alignment of the microscope optical components cannot be overstressed. Inadequate illumination, image deterioration from lens artifacts, improper use of filters, and other errors contribute not only to inferior images, but also increase the strain of imaging specimens. Each operator should be thoroughly trained in proper use of the microscope, including lamp changeovers and centration, optical alignment, correct filtration techniques, and image capture.

Prevention

On one account, Sir David Brewster was absolutely correct. Peering down vertically through a microscope is "the worst of all positions" for making observations. His suggestion that microscopists should lie on their backs may not be entirely feasible, but it does capture one essential truth. The body can endure stationary positions for extended periods if it is in a neutral posture—a position that can be maintained without a concerted effort or contortions. A neutral body posture is essential to working efficiently and effectively at the microscope for long hours.

Not everyone is in a position to buy a new ergonomically designed microscope or workstation. For conventional microscope workstations, the key to improved ergonomics is in finding the means to modify them to fit the user rather than forcing the user into awkward positions.

Following are some basic guidelines for achieving and maintaining neutral body posture while using a microscope:

- Eyes - eyepieces should rest just below the eyes with the eyes looking downward at an angle 30 to 45 degrees below the horizontal; interocular distance of binocular eyepieces should be adjusted to ensure that both eyes are focusing comfortably.

- Neck - the neck and head should bend as little as possible, preferably no more than 10-15 degrees below the horizontal.

- Back - the individual should be sitting erect, leaning the entire body slightly forward with the lower back and shoulder blades supported by the chair and/or lumbar support cushion. Sitting for long periods places undue strain on the lower back, which can be alleviated with the proper support.

- Arms/wrists - the upper arms should be perpendicular to the floor, elbows close to the body (not winged or sticking out), the forearms parallel to the floor; wrists should be straight.

- Legs - feet should rest firmly on the floor or a footrest, and even pressure should be applied by the chair to the back of the thighs.

To further reduce ergonomic risk factors:

- Develop an awareness of posture. Try to maintain the natural curve of the lower back when sitting. Use additional lumbar support if necessary.

- If the foot ring on a lab stool is too low, raise it to keep the lower back supported by the chair back. Often, laboratory bench leg-wells are utilized as storage facilities for seldom-used equipment and extra supplies. Clear this area so that legs and feet are not impeded while sitting at the bench.

- Don't lean forward to look through the microscope. Instead, adjust the position of the chair, workstation or microscope to keep the back straight and the head upright. The eyepieces should be in line with, or even extended over, the edge of the bench.

- If the microscope is too low, raise it by placing a book underneath it or modify the configuration with original equipment manufacturer (OEM) or aftermarket accessories to keep the head upright. If microscope eye-level risers are not readily available, use a three-ring binder to tilt the microscope so the eyepieces are placed at a more suitable angle. For a long-term solution, either purchase a suitable OEM or aftermarket stand or have one adequate for the purpose constructed locally.

- Adjust the height of the microscope, bench, or chair to avoid bending or extending the neck, or jutting the chin forward. If standing, the operator should have anti-fatigue mats installed at the microscope workstation to ease the burden on the feet, legs, and lower back.

- Check the seat platform for tilt and height to maintain even pressure along the back of the thighs. In situations where it is possible, use an industrial-height footstool for better posture and position. This allows the operator to bend forward at the hips rather than the neck, back, and shoulders.

- Avoid contact stress from forearms resting on sharp bench or counter edges by adding padded edge protectors. Operating the focus and stage controls with the arms separated from the bench (lifted) for extended periods can induce static loading fatigue, which can be reduced with the proper support, such as padded and tilted armrests. Also, if laboratory layout permits, utilization of cut-out work tables or laboratory benches with recessed tops allow the operator to spread out and more efficiently employ auxiliary equipment necessary for microscopy observations and manipulations.

- Ensure that the microscope optical train is configured properly and the illumination source is aligned and performing optimally. Adjust eyepiece interpupillary distance, diopter settings, and check the parfocality. The eyepieces should be approximately the same distance from the observer's eyes, rather than one being closer than the other. Eyepoint should be low enough that the field of vision is completely filled, but far enough away to avoid contact of eyepieces with the eyelashes. If the eyepieces are not properly focused, the eyes tend to compensate, which leads to increased headaches and eye fatigue. Buy plan-corrected objectives that produce flat viewfields. Microscopes with significant field curvature are difficult to use, especially for extended periods of time, during which the operator must continuously refocus the specimen to examine the entire field. Excessive microscope illumination can cause an uncomfortably high level of light and contrast, which is easily reduced by proper adjustment of the lamp voltage and the condenser aperture. Any of these factors can be a contributing cause of eyestrain.

- Operators that wear eyeglasses can adjust the eyepieces to accommodate near and far sightedness, but those who have more severe conditions should see an optician to determine whether they are suited for extended observation periods using a microscope. Simple adjustment of the eyepiece diopter cannot correct for astigmatism and some of the other, more serious, visual difficulties. In cases of extreme astigmatism and fusion insufficiency (poor eye coordination), the operator may require assistance of digital video equipment and a computer monitor or television screen to enhance, or replace, the eyepieces.

- Check the laboratory environment for excessive glare and reflections from overhead fluorescent lighting, and adjust external and internal microscope light to compensate for this artifact.

- Other environmental factors such as temperature, humidity, air currents, ventilation, excessive noise, and ambient lighting levels will also affect operator comfort and fatigue, especially over extended periods of time. Adjust these variables, whenever possible, to make the laboratory environment as comfortable as possible. The nominal temperature range is between 19 and 23 degrees Celsius (66 to 73 degrees Fahrenheit), with ideal relative humidity averaging between 40 and 60 percent. Low humidity conditions lead to drying of the eyes, which further aggravates eyestrain.

- Regular breaks from the microscope, ranging from five to ten minutes per hour, are essential to reduce fatigue, especially for operators who work at microscope workstations for six to eight-hour shifts. Periodic resting of the eyes, neck, and shoulders allows operators to work for extended periods without experiencing stress-related injuries. Bending, flexing, rotation, extension, and stretching exercises during these breaks often help to alleviate stress and will greatly benefit the operator's health in the long term. In fact, some companies have implemented a routine exercise program during short break periods. Another mechanism employed to relieve fatigue is to intermix other duties on a regular basis to reduce the length of microscopy sessions.

The amount of time a microscopist spends at a workstation should be taken into account when evaluating workstation modifications. The minimum requirement for all seated workstations is good seating, with an adjustable chair and a footrest if necessary; anti-fatigue mats should be used for workstations that require the microscopist to stand. The chair should have a pneumatic, adjustable seat pan with a sloping "water fall" edge, a backrest that is adjustable for both height and angle, height adjustable armrests, and a five-pointed star base with caster wheels.

For some seated workstations, a footrest may be appropriate. It should provide stability and firm contact with the floor and a surface texture that keeps the feet from sliding off. It should be readily adjustable to accommodate varying user heights and have an angle of approximately 10 degrees. Toes should be above the heel, allowing the lower leg muscles to stretch.

Additional recommendations based on time spent per day at the microscope:

- Adequate clearance (a minimum of 2 inches) between the thigh and desk or counter with the leg-well free from obstructions.

- Microscope tilted slightly forward or utilization of wedges, extenders, and/or eye-level adjustments.

- Proper arm support, keeping the limbs close to the body with the forearm parallel to the floor and resting on the bench top. Use armrests for older microscopes having controls located in high positions.

- Padded edges for workstations or countertops to avoid contact stress on arms.

- Adjustable microscope eyepieces should be installed, if possible.

- Electrically powered focus adjustments and objective rotation if more than half the total time on the microscope is spent twisting the coarse and fine knobs while changing the magnification factor (rotating objectives).

- Adjustable microscope eyepieces and ergonomically positioned microscope controls.

- Electrically powered focus and objective rotation. If configurations permit, powered control of the condenser aperture diaphragm, illumination intensity, and beamsplitters.

- Video monitor or television screen for examination of repetitive specimens (the monitor should be placed in the operator's primary field of view).

- Easily adjustable work surface variables, such as bench height, armrest base angle, observation eye-level, and microscope height (essential in a multi-user workstation environment).

Microscopists can also benefit from general workplace ergonomics. Reduce fatigue by reducing or eliminating highly repetitive tasks and take micro-breaks, 20-180 seconds at 10 to 15 minute work intervals. Use this time to stand and/or stretch, and allow the eyes to focus at a distance. Objects that must be accessed frequently should be kept close enough to avoid having to stretch and strain, usually within a distance of 9-19 inches. Less frequently utilized objects can be kept at a distance of 9-25 inches.

Conclusion

OSHA is continuing to formulate new ergonomics standards that will require employers to assess employee exposure to ergonomic risk factors in general industry jobs. The governmental organization estimates that the new standards, if implemented, will save employers $9.1 billion annually for the next 10 years, and prevent 460,000 reported MSDs a year (perhaps even more, if unreported cases are included).

Among the concerns of OSHA officials is that basic information about common MSDs, risk factors, and the importance of reporting symptoms be impressed upon employees who must spend a significant portion of their work day at the microscope. Although many of the ergonomic requirements are now being addressed by microscope manufacturers, there are a considerable number of microscopes "in the field" that are poorly equipped to provide worker comfort and reduce the incidence of injuries. Over time, these microscopes will be replaced with modern, ergonomically designed versions, but in the meantime, employers should be concerned about potential medical problems that may arise from extended microscope use. If a worker's job routinely involves exposure to one or more of five known ergonomic risk factors: repetition, force, awkward postures, contact stress and vibration, then some adjustment of the work environment is necessary. Aftermarket accessories, which are available for a wide spectrum of microscopes, may be the answer for a majority of older instruments in the interim. However, the end result should be migration to microscopes designed to optimize both operator safety and comfort, while providing the latest features in regard to optical quality and performance.