The Bräce-Köhler Compensator

The Bräce-Köhler compensator is ideally suited for measuring very small phase retardations (optical path differences) that are often found in living organisms, thin films, and glasses having low strain birefringence. The device can also be employed to emphasize contrast in polarized light microscopy investigations of weakly birefringent specimens in order to enhance observation of textures that display minute retardation values. Similar to many other birefringence measuring devices, the Bräce-Köhler compensator can be used to differentiate between slow and fast axes in birefringent specimens. The combined features of a Bräce-Köhler compensator render the instrument a highly sensitive and accurate device for conducting quantitative retardation measurements.

The basic features and assembly of a typical Bräce-Köhler compensator are illustrated in Figure 1. The compensator is constructed using a rectangular slider frame that contains both the compensator crystal and the mechanical gearset utilized to rotate the circular birefringent plate around the microscope optical axis. Attached to the slider frame is the control unit, housed in a larger box-like frame, which contains the crystal rotation angle readout indicator and the rotation angle adjustment dial. The slow axis of the compensator crystal at zero degrees of rotation is specified by a two-headed arrow in white paint on the upper portion of the control unit. Rotating the adjustment dial produces a corresponding rotation of a cylindrical drum behind the readout window that, in conjunction with the graduated dial, indicates the angle of the compensator with respect to the microscope analyzer and polarizer.

In practice, the compensator is inserted through a standardized DIN slot (6 × 20 millimeters) into the optical train of a polarized light microscope at a 45-degree angle (Northwest-Southeast) to the polarizer and analyzer. Most microscopes are designed to position the Bräce-Köhler compensator between the specimen and the analyzer, either in an intermediate tube or a slot in the nosepiece. The rotating compensator contains a very thin birefringent plate, usually cut from mica or calcite, having the optical axis parallel to the surface plane of the crystal. When the compensator is adjusted to the zero position using the plate rotation adjustment dial (see Figure 1), the slow and fast axes of the mica plate are oriented parallel to the analyzer and polarizer, respectively, and the viewfield appears very dark as it would without the compensator in position.

For performing delicate retardation measurements, Bräce-Köhler compensators are preferably operated in monochromatic light by using a green (546 nanometer) interference filter in combination with tungsten-halogen illumination or the e-line of a mercury arc-discharge lamp. Rotation of the mica plate introduces a very small optical path difference into the system, which produces elliptical polarization having a specific handedness related to the direction of rotation. Compensation is achieved when the degree of ellipticity is equal, but of opposite sense (handedness), to the light emerging from a birefringent specimen. These compensators are capable of measuring retardations, with an accuracy of approximately 0.3 nanometers, up to a fixed value that ranges between one-tenth and one-thirtieth of a wavelength, depending upon the manufacturer. The maximum range of a Bräce-Köhler compensator is achieved when the birefringent mica crystal axes are rotated into the 45-degree diagonal position (with respect to the microscope polarizer and analyzer vibration axes). Measurements of optical path differences exceeding the boundaries of a particular Bräce-Köhler compensator range will be inaccurate.

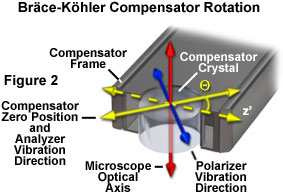

As discussed above, when using a Bräce-Köhler compensator, the microscope polarizer and analyzer remain in fixed position and the compensator crystal is rotated around the optical axis. The slow axis (having a higher refractive index) of the compensator plate (marked γ on the compensator frame) is oriented parallel to the North-South vibrational axis of the analyzer and corresponds to the zero position on the compensator dial. This concept is illustrated in Figure 2, where the solid yellow arrow corresponds to the vibration direction of the analyzer and the compensator slow axis. The red arrow in Figure 2 indicates the microscope optical axis and the blue arrow is parallel to the polarizer vibration axis. Rotating the mica plate induces an angular change in the orientation of the compensator fast and slow axes (yellow dotted line in Figure 2), which has a value indicated by the rotation angle readout indicator on the compensator housing.

To conduct a measurement, a linear birefringent specimen, such as an oriented thin film or biological macromolecular assembly (for example, a bundle of actin filaments), is placed on the microscope stage and rotated until the long axis of the specimen is positioned at a 45-degree angle with respect to the analyzer transmission axis. This maneuver yields the maximum specimen brightness. Next, the compensator dial is rotated counterclockwise from the zero position until the specimen birefringence is extinguished and matches the dark background created by crossed polarized illumination. During rotation of the compensator dial, the background remains very dark or black because the maximum optical path difference of the compensator is relatively small (fractions of a wavelength) and never exceeds one-tenth wavelength. In order to increase accuracy, the specimen can be rotated by 90-degrees on the microscope stage and a second measurement made by turning the compensator knob in the opposite direction, and then comparing the two values. Measurements along the two orientation azimuths may help to eliminate errors due to strain birefringence.

Once the specimen intensity matches that of the background, the compensator angle of rotation is used to calculate the relative retardation between the ordinary and extraordinary waves using the equation:

ΓSpecimen = ΓCompensator • sin 2(θ)

where Γ(Specimen) is the optical path difference of the specimen, Γ(Compensator) is the maximum optical path difference of the compensator (one-tenth, one-twentieth, or one-thirtieth of a wavelength), and θ is the rotation angle. In most cases, a highly accurate value of Γ(Compensator) is determined by calibration at a specific wavelength by the manufacturer and is provided on a data sheet that accompanies the compensator. Under the best conditions, retardation values down to several thousandths of a wavelength can be measured with a Bräce-Köhler compensator.

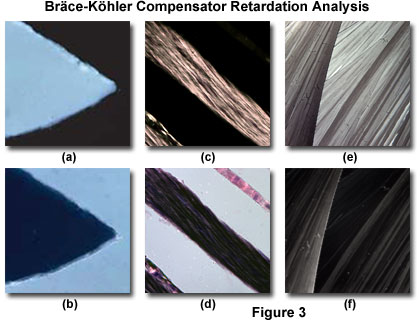

A typical series of measurements performed with a Bräce-Köhler compensator are presented in Figure 3. The polymer thin film in Figure 3(a) illustrates how the birefringent polymer appears under crossed polarized illumination either without a compensator or when the retardation plate axes are oriented parallel to the microscope polarizer and analyzer (no retardation). By inserting the Bräce-Köhler compensator and rotating the crystal axis adjustment dial, the thin film is brought to extinction (Figure 3(b)) and a measurement of birefringence can be obtained. Similarly, a thin section of human smooth muscle (Figure 3(c), polarized; and Figure 3(d), compensator) and many chemical crystal preparations (Figure 3(e), polarized; and Figure 3(f), compensator) can be analyzed with the Bräce-Köhler compensator.

In addition to conducting precise measurements of minute retardation values, Bräce-Köhler compensators are also useful for increasing contrast in thin, weakly birefringent specimens under polarized light illumination. This feature is particularly effective during observation of living specimens. Rotating the compensator dial can highlight differences between specimen and background intensity levels to reveal structures that might otherwise go unnoticed.

Sorry, this page is not

available in your country.